OHYH-200A Stainless steel semi-automatic rotary oxyhydrogen flame ampoule sealing machine

| Place of Origin: | China |

| Brand Name: | YH |

| Model Number: | OHYH-200A |

| Certification: | CE |

| Minimum Order Quantity: | 1 |

| Price: | To be rediscussed |

| Packaging Details: | Export Plywood Box |

| Delivery Time: | 2-10 working days, depends on the order quantity |

| Payment Terms: | T/T,Western Union,Moneygram,Paypal |

| Supply Ability: | 100 sets per month |

Description

Description

● The machine has a gas full automatic stop function, which produces water after combustion of hydrogen and oxygen, and is pure and pollution-free.

● The machine adopts high-power power supply, which produces rapid gas production and stable output.

● Having a dry and wet double anti-tempering device.

● Concentrated flame spray, the temperature can reach 2800-3000 degrees.

● Intelligent air cooling control, cooling and dust removal.

● With 0-100 level speed regulation and adjustment air volume, button type adjustment, more precise.

● The bottle mold is passively rotated, and the bottle is not transferred by hand to prevent burns.

● The motor rotates at a constant speed, the bottle is heated more evenly, and the sealing is more beautiful, which can achieve the effect of automatic sealing machine.

Applications

● OHYH-200A Semi-automatic rotary oxyhydrogen flame ampoule sealing machine is suitable for the drawing and sealing of 1-20ml glass ampoules in the pharmaceutical and chemical industries. It produces hydrogen-oxygen mixed gas through electrolysis principle and obtains water after combustion. It is a safe and efficient clean energy and meets GMP certification requirements. It has innovative design, small size, convenient storage, uniform flame, smooth drawing and faster sealing. It uses electrolyzed water to produce hydrogen-oxygen fuel. Compared with traditional technology, it saves time and cost, and has higher work efficiency and more safety. It is the ideal equipment for sealing the ampoule in hospitals, preparation rooms, schools, scientific research units, small pharmaceutical factories and biological preparation factories.

How does it work?

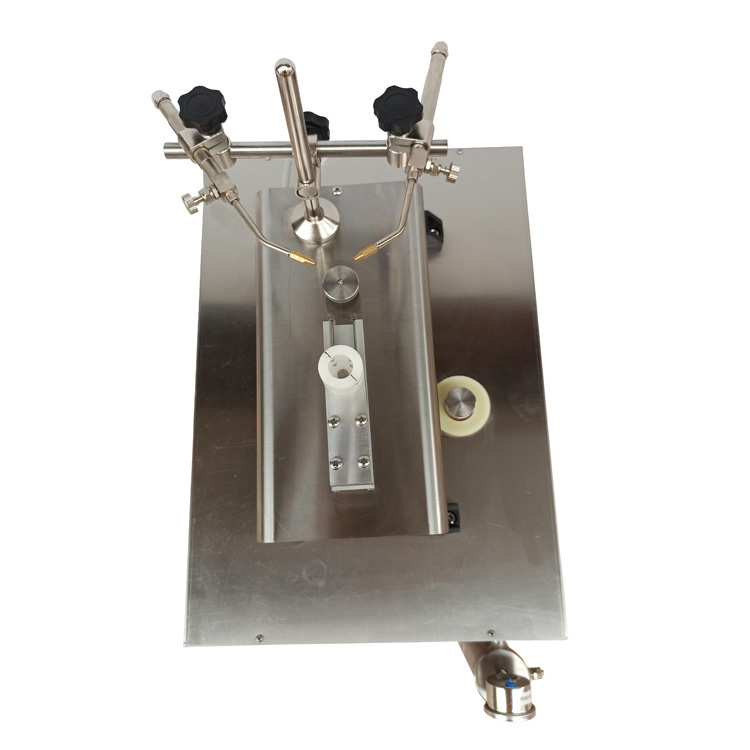

Put the ampoule bottle on the workbench, there are two sets of oxyhydrogen flame melting,automatic rotating the workbench, manual seal the ampoule by tweezers. The sealing speed can be about 40~45 pieces ampoule per minute.Other applications: suitbale for maxium 12mm diameter, 15mm length quartz glass tube sealing.

Competitive Advantage

Technical Specifications

| Power | 1000w |

| Gas production | 200L/H |

| Use voltage | 220V |

| Working current | 120A |

| Working pressure | 0.08-0.15map |

| Soft water usage | 0.06L/H |

| Oxyhydrogen flame ampoule sealing machine weight | 25kg |

| Oxyhydrogen flame ampoule sealing machine dimension | 55*33*45cm |

| Rotating table weight | 2.4kg |

| Rotating table size | 30cm*15cm*13cm |

| Plywood box dimension | 80*45*50cm |

| Plywood box weight | 31kg |

1.16 years professional pharmaceutical machinery manufacturer and supplier.

2.3 Years Warranty, 14 Days Delivery, Factory Price.

3.5680 ㎡ factory, Own R&D Team.

4.Free desian service, free professional solutions.

5.Accept the non-standard customized products.

6.Passed Iso 9001. CE. sGs. Intetek certificates.

Changsha Yiguang Pharmaceutical Machinery Co., Ltd. has a history of 15 years experience in manufacturing pharmaceutical machinery and packing machinery. our machines are widely applied in many fields, such as pharmacy, foodstuff, health care product and chemical industry. We have provided services and machines to many different countries and regions in the whole world, such as America, Europe, Oceania, South America, West Asia, Middle East and South-east Asia etc.

Our company registered capital is 10 million RMB. Located in Changsha City,the capital city of Hunan Province, With convenient transportation and excellent port conditions, Can provide complete procurement, customs clearance, installation, debugging training oversea services for customers.

Our main products include the following: 01.high efficiency wet granulator, 02.pellet granulating and coating machine, 03.roller compactor, 04.fluid bed dryer, 05.three dimensional mixer, 06.capsule filling machine ,07.tablet/pill press machine ,08.capsule/ pill / tablet counting machine ,09.blister packing machine,10.cartooning machine,11.ampoule filling and sealing machine etc.

Over the years, our company has been adhering to the concept of customer first, service priority, dedication to serve everyone, improve customer competitive advantage as our responsibility, to provide customers with high quality and competitive prices, welcome customers to call us or visit us.

Our certificate

1. What about your Pharmaceutical machine quality?

Our factory has more than 10 years experience in mechanical processing,exported into many countries and areas; already got customer’s good reputation.

2. What about your Pharmaceutical machine price?

Anytime we will make quality as factory life, no matter price is good or not for us. Quality is first, on the top quality basis, Sure you will get reasonable and satisfied price!

3. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

4.What about your installation service and sales service for machine?

1.Guarantee is one year, we will supply spare parts or send engineers to your side if you need, we will give you service anytime, 24 hours, 7days.

2.We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.

3.It is free to train your worker in our factory or in your side or by video.

EN

EN  AR

AR JA

JA RU

RU DE

DE TR

TR FR

FR