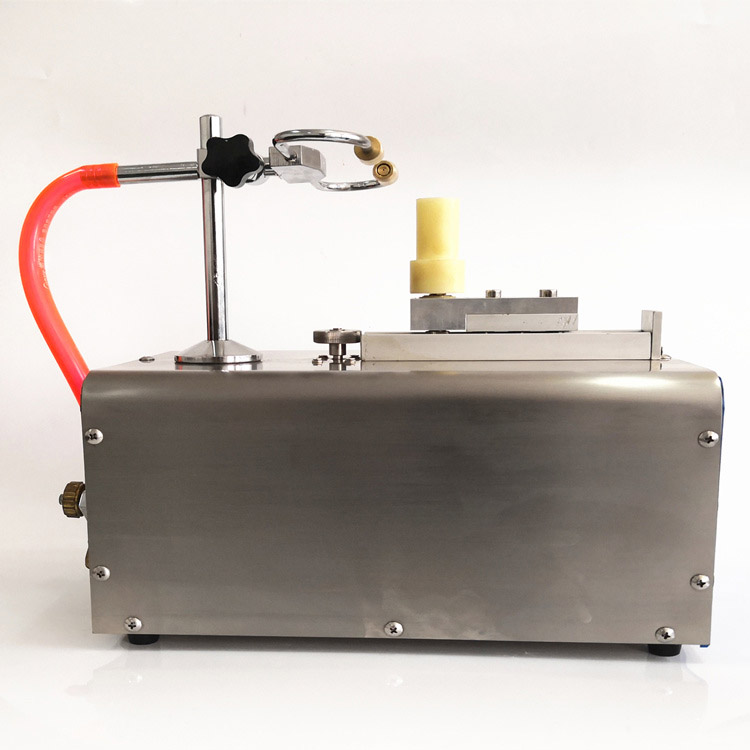

GBS-1 Semi-automatic rotary ampoule sealing machine

| Place of Origin: | China |

| Brand Name: | YH |

| Model Number: | GBS-1 |

| Certification: | CE |

| Minimum Order Quantity: | 1 |

| Price: | To be rediscussed |

| Packaging Details: | Export Carton Box |

| Delivery Time: | 2-10 working days, depends on the order quantity |

| Payment Terms: | T/T,Western Union,Moneygram,Paypal |

| Supply Ability: | 1000 sets per month |

Description

Description

● This machine is suitable for 110v/220v power supply, universally used.

● With 0-100 level speed regulation and adjustment air volume, button type adjustment, more precise.

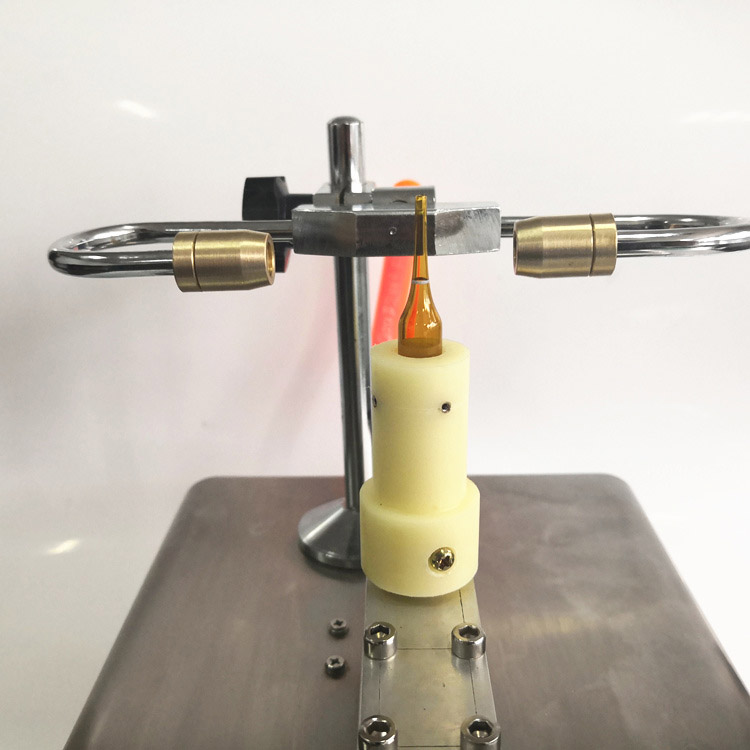

● The bottle mold is passively rotated, and the bottle is not transferred by hand to prevent burns.

● The motor rotates at a constant speed, the bottle is heated more evenly, and the sealing is more beautiful, which can achieve the effect of automatic sealing machine.

● The bottle mold is fixed with elastic beads to minimize the eccentricity during the rotation process.

● The air pump has been updated, using a uniform speed adjustment, uniform gas output, and powerful injection, completely solving the problem of initial gas supply intermittent.

● No training, easy to use, no experience can seal good looking bottles.

OPERTAING PRINCIPLE

The filled, unsealed glassware is placed on the workbench and directed onto a motor-driven rotating roller, causing the ampoule or tube to spin in front of a burner head. The gases are employed usually oxygen blended with combustible gas (propane, city gas or acetylene) then fed through a venture mixer from your source tanks. Once the blendedgases are ignited, the operator adjusts the flame to its peak effectiveness and directs it at the desired point of seal. When cooling the product, the sealed glass container is removed from the roller section and placed on the convenient cooling shelf. The YH GBS-1 Ampoule Sealer is ideal for lab or small scale production facilities in the Pharmaceutical, Biotechnology and Animal Health industries

Applications

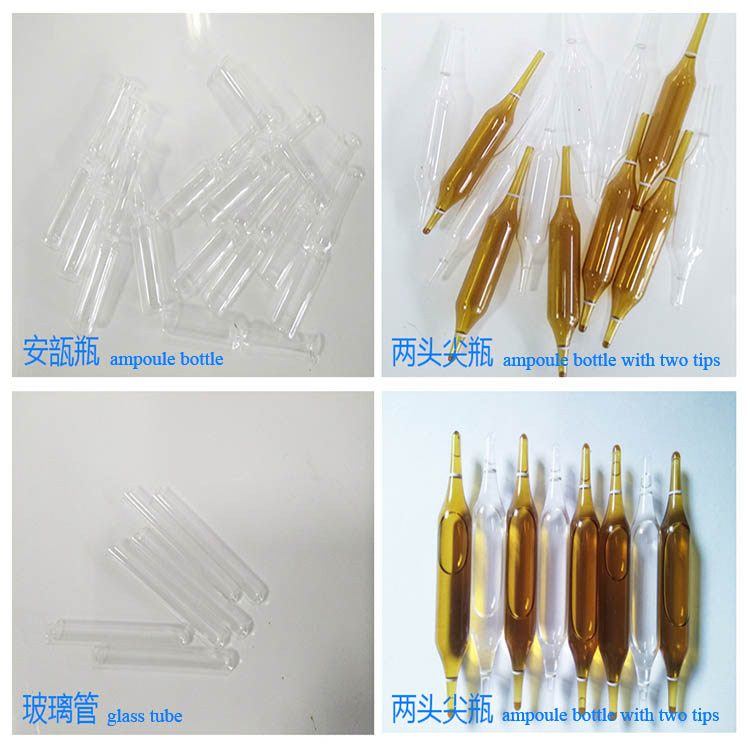

● GBS-1 semi-automatic rotary ampoule sealing machine is mainly used for hot melt sealing of glass products such as ampoules and control bottles. It is suitable for school teaching、laboratory research and development、 small batch trial sealing, widely used in pharmaceutical、 chemical,、environmental、biological、 beauty and other industries. Petroleum liquefied gas (gas) and natural gas originate from the air-generating device, so that the flame is concentrated and sprayed to achieve the purpose of sealing.

Competitive Advantage

Technical Specifications

| Production capacity | 600b/h |

| Input voltage | 110v/220v |

| Total power | 25w |

| Gas production | 4L/min |

| Air pressure | 100kpa |

| Package Size | 40*30*50cm |

| Weight | 5kg |

1.16 years professional pharmaceutical machinery manufacturer and supplier.

2.3 Years Warranty, 14 Days Delivery, Factory Price.

3.5680 ㎡ factory, Own R&D Team.

4.Free desian service, free professional solutions.

5.Accept the non-standard customized products.

6.Passed Iso 9001. CE. sGs. Intetek certificates.

Changsha Yiguang Pharmaceutical Machinery Co., Ltd. has a history of 15 years experience in manufacturing pharmaceutical machinery and packing machinery. our machines are widely applied in many fields, such as pharmacy, foodstuff, health care product and chemical industry. We have provided services and machines to many different countries and regions in the whole world, such as America, Europe, Oceania, South America, West Asia, Middle East and South-east Asia etc.

Our company registered capital is 10 million RMB. Located in Changsha City,the capital city of Hunan Province, With convenient transportation and excellent port conditions, Can provide complete procurement, customs clearance, installation, debugging training oversea services for customers.

Our main products include the following: 01.high efficiency wet granulator, 02.pellet granulating and coating machine, 03.roller compactor, 04.fluid bed dryer, 05.three dimensional mixer, 06.capsule filling machine ,07.tablet/pill press machine ,08.capsule/ pill / tablet counting machine ,09.blister packing machine,10.cartooning machine,11.ampoule filling and sealing machine etc.

Over the years, our company has been adhering to the concept of customer first, service priority, dedication to serve everyone, improve customer competitive advantage as our responsibility, to provide customers with high quality and competitive prices, welcome customers to call us or visit us.

Our certificate

1. What about your Pharmaceutical machine quality?

Our factory has more than 10 years experience in mechanical processing,exported into many countries and areas; already got customer’s good reputation.

2. What about your Pharmaceutical machine price?

Anytime we will make quality as factory life, no matter price is good or not for us. Quality is first, on the top quality basis, Sure you will get reasonable and satisfied price!

3. How can you ensure the machine’s quality after we put the order?

Before the delivery, we will send you machine’s pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

4.What about your installation service and sales service for machine?

1.Guarantee is one year, we will supply spare parts or send engineers to your side if you need, we will give you service anytime, 24 hours, 7days.

2.We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.

3.It is free to train your worker in our factory or in your side or by video.

EN

EN  AR

AR JA

JA RU

RU DE

DE TR

TR FR

FR